Broadmeadow is an underground coal mine in Queensland outputting roughly 6 million tons a year.

Stage 1

A single pump was fitted with a controller at a workshop sump. A data logger was used to measure air consumption over 24 hours. It was shown that run time in this application was reduced by 94%.

Stage 2

Six units were deployed throughout the mine in various roles to test the long term reliability and suitability. These units were in service been in use for over 1 year. We have had only one unit fail due to wear.

Stage 3

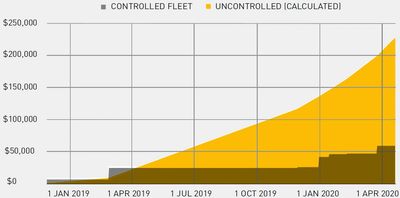

A panel was fitted with 7 controlled pumps and data collected from the air supply in to the panel. Data was collected for approximately 1 month. It was shown that controllers reduced total air consumption by 74%.