Client

Tier 1 Coal Mining company within Australia

Products Used

Rock Monitor XR SystemCompany

Tier 1 mining client with underground operations.

The Challenge

A mining client was installing six 8-meter fully grouted bolts per meter in underground roadways as dictated by numerical modelling and risk assessments. However, manual inspections and data collected from traditional instrumentation were insufficiently conclusive to support a reduction in support densities. This resulted in:

- Over Bolting: Excessive use of support materials beyond the actual requirements.

- Increased Costs: Higher material and labour expenses due to unnecessary bolting.

- Production Delays: Additional installation time slowed down operational throughput.

The company needed a solution that could provide clear, real-time strata behaviour data to inform their support density decisions confidently and reduce wasteful over bolting.

The Solution!

To address these challenges, the client implemented Nome’s RockMonitor system -a real-time strata monitoring solution designed for underground applications. By replacing manual inspections and traditional data sets with automated, continuous monitoring, the company achieved:

• Data-Driven Decision Making: Real-time and historical strata movement data allowed engineers to confidently adjust support densities without compromising safety.

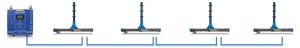

• Comprehensive Coverage: Electronic telltales installed throughout the underground roadways provided detailed strata condition information over a wide area.

• Integration with Existing Systems: The system seamlessly integrated with SCADA platforms like Citect and allowed remote access for data review and analysis.

• Scalability: Support for large-scale monitoring networks with up to 150 instruments per controller and multiple controllers across the operation.

Key Risk Management Features

The RockMonitor system provided enhanced safety and reliability through:

- Intrinsically Safe Design: ExiA IECEx and ATEX certifications enabled safe operation in explosive environments (ERZ1/ERZ0).

- Real-Time Alerts: Automated notifications for strata movement anomalies and other critical events.

- Portable Diagnostics: Certified portable readers for efficient troubleshooting and validation of installed equipment.

- System Scalability: The ability to expand the monitoring network as operational needs evolved.

The Outcome

By leveraging the RockMonitor system, the client achieved:

- Reduced Support Densities: Real-time data confirmed that fewer bolts were sufficient to meet safety requirements, cutting material usage without compromising safety. A reduction to 4 x 8 meter fully grouted bolts per meter was implemented safely.

- Cost Savings: The reduction in bolting requirements resulted in significant savings in material and labour costs.

- Improved Productivity: Shortened installation times allowed for faster roadway development and minimized production delays.

- Enhanced Safety Assurance: Continuous monitoring provided confidence in the adjusted support densities, maintaining compliance with safety standards.

- The overall expenditure to implement RockMonitor through this asset was <$250,000 USD. The cost savings derived from the data provided and resulting in reduced bolting densities and added efficiencies was >$16,000,000 USD. This represents an annualized ROI of 6,400%.

Conclusion

The implementation of the RockMonitor system enabled the client to transition from conservative, over-bolting practices to a data-driven approach. This not only reduced operational costs but also optimized productivity without compromising safety. The case demonstrates the value of real-time monitoring in modern mining operations as a means to refine support practices, enhance safety, and improve overall efficiency.