The MK3 is a retrofitted controller that improves the service life of your diaphragm pumps and reduces electricity and maintenance costs.

FINALIST 2019 AUSTRALIAN MINING PROSPECT AWARDS

Effective and efficient water management is critical to maintaining asset integrity and meeting production targets. This is especially true as the industry looks for ways to do

more with less.

Diaphragm pumps have long been the industry standard for dewatering at underground mines. A major flaw of these pumps is their continuous run time, requiring significant expenditure on infrastructure and electricity to ensure sufficient air supply for operation. This leads to a relatively short service life with high electricity and maintenance costs.

The MK3 changes that.

Ultimate reliability, ultra-low maintenance

HOW IT WORKS

The MK3 Air Pump Controller runs the pump only when it’s moving water, reducing air consumption and wear while extending service life. Lower air consumption also means

maintaining line pressure throughout the mine is much easier.

Mine equipment needs to be durable, reliable, and able to function under the worst conditions. The MK3 controller is built to last, through a combination of quality materials and solid engineering. It can be fitted in 15 minutes and deployed in 2 minutes.

We are committed to continuous improvement and extensively test our controllers to ensure they continue to deliver outstanding results in pump operation and cost savings.

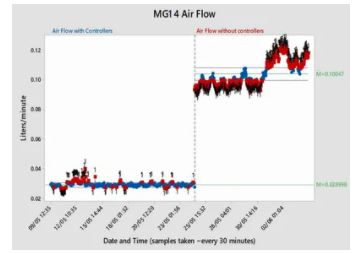

Typical Results – Trials at a Queensland Coal Mine

The Pump controller underwent an extensive trial and testing period at a Queensland underground coal mine over a period of 18 months. The staged trial saw a total of 71 controllers installed on pumps across the mine. They were in operation for a combined 15,092 days of service and mine data showed a reduction in air consumption of approx. 65 m3min-1. Annualised cost savings (maintenance and electricity) based on this trial were $705,966.

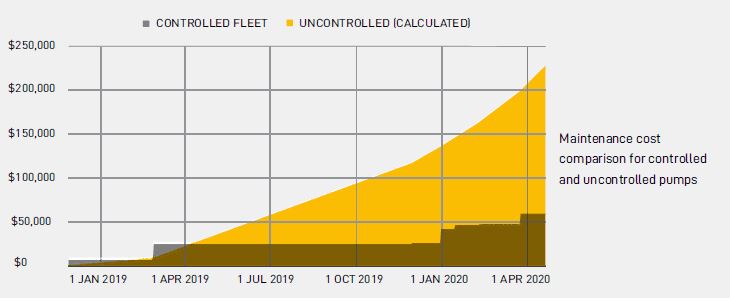

Service Life and Maintenance Costs

Due to their continuous operation, diaphragm pumps have an average service life of around 60 days. Through testing and trials, we’ve seen an exponential increase in average

pump service life to 274 days following installation of the controllers. This represents a significant saving in pump maintenance costs with service intervals extending

out to one year.

Since incorporating the MK3 pump controllers to our air pumps, we have seen overhaul durations dramatically increase from 3 months previously, to nearly 18 months currently. This is a great return on investment in maintenance alone before taking into account an increased air supply throughout our mine.

QLD Coal Mine

Outbye Coordinator

Electricity costs comparison

The energy cost of a pump without a controller fitted is approx. $6,161 per year. With approx. 84% reduction in running time, energy costs for a pump fitted with a controller is estimated at $985 per year. This represents an annual saving of $5,193 in energy costs for each pump fitted with a Nome Air Pump Controller.

*Assuming an energy tariff of $0.13307/kWh and a power demand of 5.3kW to supply 1.1 m3min-1 of air to each pump.

MK3 Brochure

CSG_SalesBrochure_Jan21_Nome_DigitalBroadmeadow Maintenance Snapshot

MK2_NOME_BRM_Maintenance Snapshot