Our Featured Product — Rock Monitor XR System

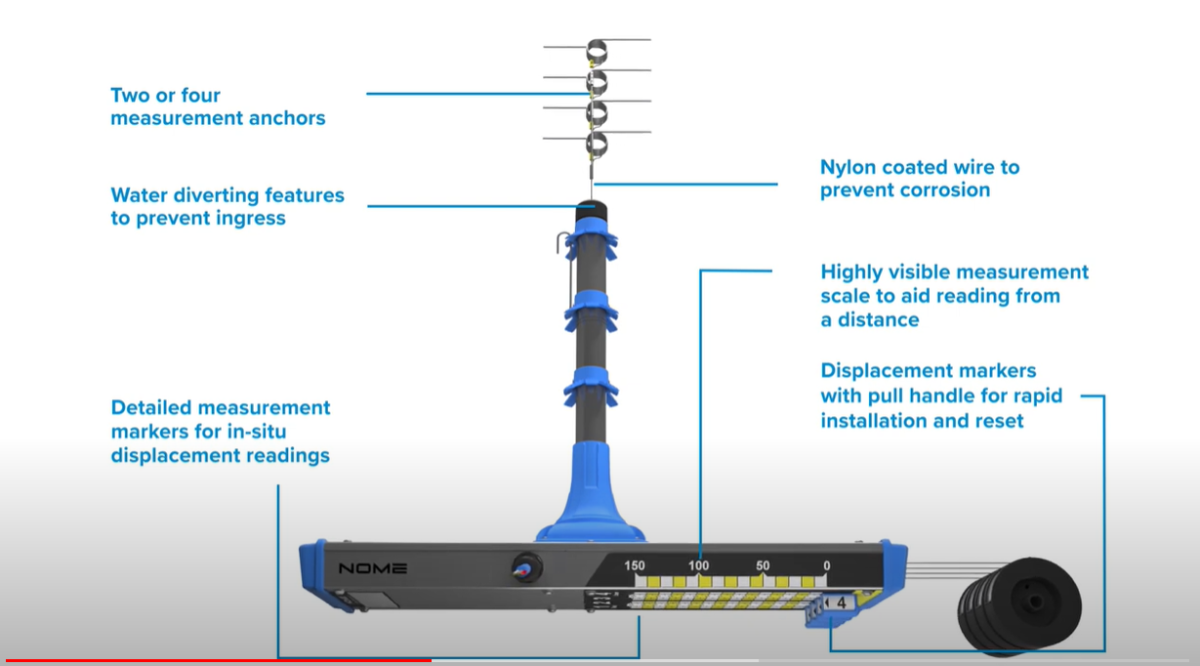

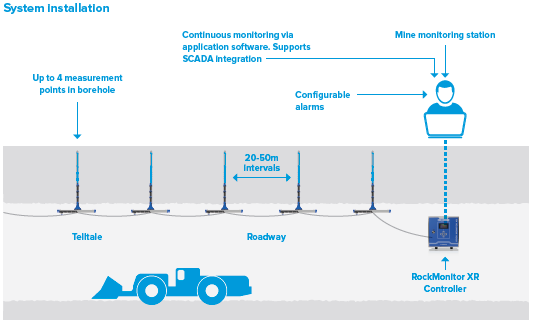

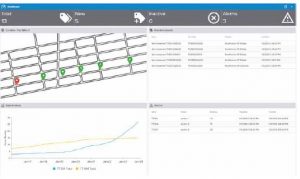

Rock Monitor XR is a fully networked solution for measuring the displacement of tunnel roof and sidewall strata in both soft and hard rock applications.

Applications of Rock Monitors

- Monitoring the integrity of rock structures in underground mining and tunnelling.

- Ensuring the highest levels of worker safety.

- Providing continuous data to allow optimization of roof support planning.

Why Are Rock Monitors Essential?

In short, they are your safeguards against potential safety and injury problems. Observing and monitoring roof movement gives valuable information that can be used to make critical safety decisions. On principle, underground mines employ observational techniques to take note of roof stability, which isn’t the most efficient or accurate. Mineworkers have practised “sounding” the rock. This entails striking areas and listening for sounds that signal loose rocks. Other methods include load cells, electromechanical roof monitors, microseismic monitoring, or mechanical measurement.

Falling grounds are often responsible for injurious and fatal incidents in the coal mining industry. Where rock monitors can provide information related to rock stability from geologic discontinuities or existing weakness, they prove valuable in increasing safety and efficiency. Monitoring the ground continuously in response to coal mining is essential to keep track of changing pressures, displacements and seismicity. The availability of this data is required to reach key decisions throughout any progress in nome .

The benefits associated with this product series are outstanding - a 65% reduction in injury and incident reports, 40% increase in productivity, 49% reduction in standing support costs - all independently accredited. Every mine in the world should have one of these systems installed and it’s our mission at Nome to ensure that they do.