So, what is it, and why does it matter?

Silica is a natural substance found in most rocks and is the most abundant compound in the earth’s crust. It is also present in sand, clay, and products such as bricks, concrete, and stone.

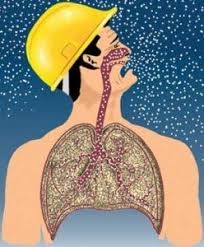

In the workplace, these materials create dust when they are cut, drilled, sanded down etc. Some of this dust may be fine enough to reach deep inside the lungs and may contain respirable crystalline silica (RCS), and in particular quartz particles, that can cause harm to health. Exposure over a long period of time can cause fibrosis (hardening or scarring) of the lung tissue with a consequent loss of lung function.

Key conditions that can arise include silicosis, chronic obstructive pulmonary disease (COPD), and kidney disease, and is associated with the development of lung infections, autoimmune disorders, and cardiovascular impairment. Sufferers are likely to have severe shortness of breath and may find it difficult or impossible to walk upstairs or even short distances. The effect continues to develop after exposure has stopped and is irreversible.

Therefore, it is imperative that a thorough monitoring procedure should be implemented to prevent unnecessary serious illnesses of those who work in this industry.

“An estimate from the Cancer Burden Study of the number of deaths from lung cancer associated with exposure to RCS shows there are around 600 deaths per year with 450 of these occurring from exposures in the construction sector alone (UK figures).” HSE